As experts in on-site HDPE pipe fusion, we know what it takes to install a pipe system that functions effectively, efficiently, and safely. One part of the process that often slips people’s minds is de-beading. But remembering to complete this step is critical if you want your pipe system to operate at maximum capacity.

Here’s what you need to know about de-beading HDPE pipes.

How Do HDPE Pipe Beads Form?

HDPE pipe beads form during the butt fusion process. Sections of HDPE pipe must be heated to fuse them together. When they’re heated, the HDPE material starts to melt — and when force is applied to fuse the pipes together, circular melt beads form as excess material is pushed inward or outward.

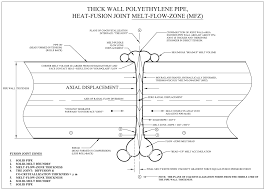

That excess material then forms to make HDPE pipe beads, which will form on both the outside and inside of the pipe. Here’s a good diagram from the Plastics Pipe Institute of what those HDPE pipe beads might look like:

Butt fusion is one method of fusing two sections of HDPE pipe together. It employs a fusion machine to hold two pieces of pipe while the ends are heated with a heater plate. Once heated, force is used to firmly push the two ends together where they are left to connect, cool, and seal.

Butt fusion is the most common and best method of fusing two straight sections of pipe together. The fused joints often end up being stronger than the pipe itself. However, the process can create beads on the inside and outside of the fused joints that can be removed to achieve peak pipe performance in certain applications.

Why Is It Important to Remove HDPE Pipe Beads?

Not every application requires removal of HDPE pipe beads during butt fusion, but it is necessary in some circumstances (e.g. conduit lines). Here’s why.

Internal HDPE pipe beads can create blockages within the pipe. These blockages can restrict flow, trap bacteria and biofilms, and result in pipe wear due to turbulent flow. By removing internal beads, you can eliminate those blockages, reduce friction, and allow for better, healthier flow throughout the pipe.

How to De-Bead HDPE Pipes

HDPE pipe beads can be removed using special bead remover tools. Also referred to as “de-beaders,” these HDPE pipe installation tools help remove the beads on the inside or outside of the pipe.

- An internal pipe de-beader is a longer, pole-shaped tool that can reach up the length of the pipe. It uses a drive handle and cutter head to reach in and cut the bead away from the interior. Standard internal de-beaders are ideal for pipe diameters between 3.5-17.7in, but larger ones are available to suit pipe diameters up to 31.5in.

- An external pipe de-beader is a type of run-around planing tool. It digs into the bead and uses a ratchet motion to smoothly cut it off. These tools are also frequently used in sliplining and casing processes to repair leaks.

Either way, HDPE pipe de-beading is a relatively quick process if you have the right team and equipment. In most cases, contractors include it in their pipe installation and fusion services.

For Expert HDPE Pipe Installation Services, Contact US FUSION.

If you’re in need of HDPE pipe fusion and bead removal, trust US FUSION. With ASME Section IX-certified fusion technicians and a fleet of fusion machines in stock, we’re ready to provide experienced, reliable, and safe pipe fusion services for a variety of applications. Our processes meet the highest industry standards and environmental regulations, allowing us to ensure a job well done each and every time.

For more information, give us a call at (225) 647-2747 or contact us online.