Unlocking Durability: Commercial Rubber Lining Solutions Explained

Rubber lining is a crucial part of many industrial processes that often goes unnoticed but offers significant benefits. It involves coating the inside of pipes, tanks, and equipment with a protective layer of rubber, acting as a strong barrier against corrosion, abrasion, and chemical exposure. This process significantly prolongs the lifespan of industrial equipment, making it an essential practice in various industries such as chemical plants, mining, water treatment, and food processing.

Discover the Remarkable Benefits of Rubber Lining

Rubber lining systems are highly praised for their excellent performance in protecting industrial equipment from various damaging forces. Apart from their protective qualities, they also provide operational advantages, making them a vital choice for equipment longevity.

Corrosion Resistance

The rubber lining acts as a strong shield against corrosion, providing a protective barrier for industrial equipment exposed to corrosive substances. The resilience of rubber lining enables machinery to withstand harsh conditions, significantly extending its service life.

Abrasion Resistance

Durability is a key feature of rubber lining, offering resistance against wear and tear caused by abrasive materials. This durability results in reduced maintenance costs and minimizes unscheduled downtime associated with repairs, making it a cost-effective solution.

Chemical Resistance

The inherent resistance to various chemicals makes rubber lining the preferred material for tanks and pipes involved in aggressive chemical processing. This not only protects the container but also ensures the safety of its contents.

Impact Absorption

The shock-absorbing properties of rubber lining are crucial for equipment handling high-impact materials. This feature helps equipment withstand shocks and vibrations, maintaining structural integrity and reducing the need for frequent maintenance.

Cost-effectiveness

Considering long-term operational costs, rubber lining proves to be a cost-effective solution. Its ability to prevent frequent equipment replacement and its minimal maintenance requirements make it a smart and economical investment for industrial applications.

Exploring the Versatility of Rubber Lining Applications

Rubber lining is versatile and finds applications in various industries due to its superior protective qualities. It proves to be a go-to solution for various applications, balancing protection and performance effectively.

Some common applications include:

- Industrial Tanks and Vessels: Prevents corrosion and leakage in tanks and vessels.

- Pipes and Ducts: Protects pipes, reduces noise, and extends the lifespan of the network.

- Chutes and Hoppers: Minimizes friction and abrasion in material handling.

- Conveyor Systems: Mitigates damage to conveyor belts and systems, enhancing efficiency.

- Mining Equipment: Essential for crushers and grinding mills in harsh mining environments.

- Chemical Processing Equipment: Lining prevents corrosion, providing insulation and safety.

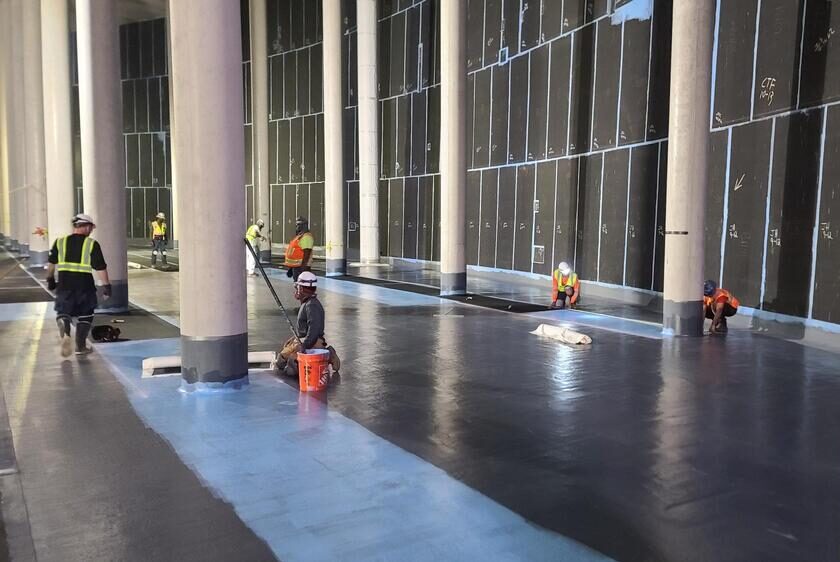

Ensuring Excellence: The Rubber Lining Installation Process

The installation of rubber lining is critical for its performance and longevity. The process involves:

- Surface Preparation: Thorough cleaning to remove rust, scale, and contaminants.

- Adhesive Application: Applying specialized adhesive evenly for a strong bond.

- Rubber Sheet Application: Meticulously positioning rubber sheets for complete coverage.

- Vulcanization Process: Heat and pressure enhance the bond’s strength.

- Quality Control Measures: Stringent checks at every step ensure reliability and effectiveness.

Maintenance and Longevity of Rubber Lining

Maintaining rubber linings is crucial for their integrity and extended service life. This involves routine inspection, timely repairs, and understanding factors affecting longevity. With consistent oversight and proper care, rubber lining continues to safeguard equipment effectively.

Inspection and Monitoring

Routine inspection and monitoring are the cornerstones of preserving the quality of your rubber linings. It is important to implement a schedule that includes checking for signs of wear, chemical degradation, and mechanical damage. Regular assessments ensure that you can identify and address issues before they escalate into major problems, prolonging the life of your rubber installations.

Repairs and Re-lining

Should an inspection reveal any concerns, timely repairs are imperative. In instances where damage is beyond simple fixes, re-lining might be the most viable path forward. Skilled professionals can assess the situation and provide the necessary services to restore your rubber linings to their optimum condition, ensuring continuous protection against corrosive or abrasive materials.

Longevity of Rubber Lining

The typical lifespan of rubber lining varies depending on several factors, including the type of rubber used, the environment it’s exposed to, and the frequency and thoroughness of maintenance. However, with adequate care, rubber linings can last many years, protecting your equipment from harsh conditions and potentially saving your business from significant repair costs or downtime.

- Implement a consistent inspection schedule to catch and resolve small issues early.

- Engage with specialists for repairs to ensure that the integrity of the lining is maintained.

- Understand that the longevity of your rubber lining is directly linked to proactive, preventative maintenance practices.

With diligent oversight and proper care, your rubber lining will continue to serve its purpose, safeguarding your valuable assets for the long haul.

Key Factors to Consider When Choosing a Rubber Lining

Selecting the right rubber lining is crucial for durability, safety, and cost-effectiveness. Considerations include:

-

Type of Rubber Material: Natural or synthetic rubber based on specific application needs.

-

Thickness Requirements: Adequate thickness for protection against corrosion and wear.

-

Compatibility with Substances: Ensure compatibility with substances encountered.

-

Environmental Factors: Consider temperature, UV exposure, and mechanical stresses.

Consulting a specialist is advisable to ensure a perfect fit for the application and prevent suboptimal performance.

Industry Standards and Regulations for Rubber Lining

Adherence to industry standards and regulations is vital for the successful implementation of rubber linings. Ensuring compliance with these standards is fundamental for safety, environmental protection, and maintaining consistent quality. Key areas include:

- Compliance with Safety Standards: Adherence to OSHA, ISO 45001, and other safety guidelines.

- Environmental Regulations: Compliance with EPA, ISO 14001, and other environmental standards.

- Quality Assurance: Following ISO 9001 for quality management systems ensures durability and reliability.

Securing Your Assets: The Definitive Advantages of Rubber Lining

Rubber lining plays a crucial role in industrial and commercial applications, offering benefits such as protection, longevity, and cost-effectiveness. It acts as a robust fortress for investments, ensuring durable and efficient operation of machinery and storage solutions.

Make the Right Choice for Lasting Durability and Protection

Equipping assets with rubber lining is not just a choice but an intelligent and strategic decision for enhancing durability and ensuring exceptional protection. Embrace the resilience of rubber lining to safeguard equipment and secure the future of your industry.