Pipe Fusion Series: What Is Butt Fusion?

Butt fusion is a widely used welding technique in the field of thermoplastic piping systems. This method plays a crucial role in joining pipes and fittings, ensuring leak-proof connections, and maintaining the integrity of fluid transportation networks. This article explores the fundamentals of butt fusion, its applications, plus some advantages and disadvantages of the technique.

What Is Butt Fusion?

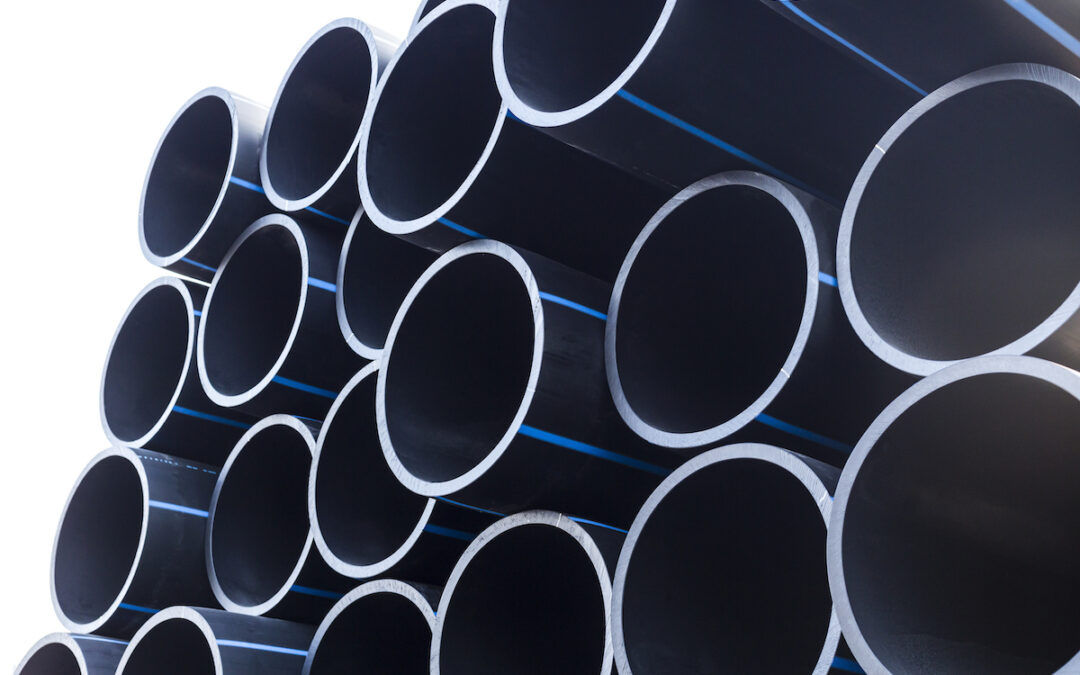

Butt fusion is a thermal welding process used primarily for joining pipes and fittings made from thermoplastic materials such as polyvinylidene fluoride (PVDF) and high-density polyethylene (HDPE). The name “butt fusion” derives from the way the two pipe ends are brought together, creating a seamless, end-to-end connection.

Butt Fusion Process

The key steps involved in butt fusion include:

1. Pipe Preparation

The ends of the pipes to be joined are cut square and cleaned to remove any dirt, debris, or oxidation. This ensures a clean, uncontaminated fusion surface. The fusion machine then uses a facer/cutter to cut the pipe back to original resin.

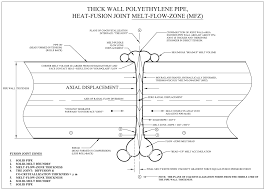

2. Heating

A butt fusion machine is used to heat the ends of the pipes. This machine features heating plates that are in direct contact with the pipe ends, allowing them to reach the required fusion temperature.

3. Fusion

Once the pipe ends are heated to the appropriate temperature, they are quickly brought together, creating a melt zone. This molten material fuses together, forming a seamless connection as it cools down.

4. Cooling and Consolidation

After fusion, the pipe and fitting are held in place while the material cools and consolidates, ensuring a strong and homogeneous joint.

Butt Fusion vs. Other Types of Pipe Fusion

Butt fusion isn’t the only effective method of pipe fusion. See how it compares to other popular pipe fusion methods like saddle fusion, socket fusion, and electrofusion.

Butt Fusion

Method: Involves joining two pipe ends by heating them to their melting point and then pressing them together. The melted material fuses, creating a seamless, end-to-end connection.

Advantages:

- Produces leak-proof and long-lasting joints.

- Suitable for a wide range of thermoplastic materials.

- No need for additional adhesives or solvents.

- Minimal maintenance is required.

- Consistent and repeatable results.

Saddle Fusion

Method: Used to create branch connections by attaching a saddle-shaped fitting to an existing pipe. The saddle is heated, and pressure is applied to weld it to the main pipe.

Advantages:

- Ideal for creating branch connections in a pipeline.

- Requires minimal excavation, making it suitable for repairs and retrofits.

- Relatively quick and simple process.

Socket Fusion

Method: Involves heating the outside of a pipe and the inside of a fitting, then inserting the pipe into the fitting, creating a secure joint when the material cools.

Advantages:

- Suitable for small-diameter pipes and fittings.

- No need for external clamps.

- Creates joints that are resistant to pull-out forces.

Electrofusion

Method: Involves connecting two ends by sliding and coupler over the ends. The coupler has coils inside that are heated up to make a leak-free pressure rate weld.

Advantages:

- Provides a strong, continuous connection.

- Suitable for creating complex shapes and custom profiles.

- Great for tight area repairs

When to Use Butt Fusion

Butt fusion is commonly used in various industries and applications, including:

- Water and Gas Distribution: Butt fusion is the preferred method for joining pipes in water and gas distribution systems. It provides leak-free connections that are critical for the safe and efficient transport of these essential utilities.

- Wastewater Management: In sewage and wastewater systems, where pipes are subjected to a variety of harsh chemicals and environmental conditions, butt fusion is the go-to method for reliable, long-lasting connections.

- Industrial Pipelines: Industries such as chemical processing, mining, and agriculture often rely on butt fusion to join pipes that transport a wide range of materials, from corrosive chemicals to irrigation water.

- Geothermal and HVAC Systems: Butt fusion is used to connect pipes in geothermal heating and cooling systems, ensuring efficient heat transfer and long-term durability.

Benefits of Butt Fusion

Butt fusion offers several advantages that make it a preferred choice for many applications:

- Leak-Proof Joints: The resulting joints are seamless and completely leak-proof, ensuring the integrity of the fluid or gas being transported.

- Longevity: Butt fusion joints are highly durable and can withstand the test of time, making them ideal for applications where longevity is crucial.

- No Need for Solvents or Adhesives: Unlike other joining methods, butt fusion does not require the use of solvents or adhesives, reducing the risk of chemical contamination.

- Low Maintenance: Once a butt fusion joint is made, it requires minimal maintenance, reducing operational costs.

- Consistency: Butt fusion offers a high degree of repeatability and consistency in joint quality.

Contact US FUSION’s Pipe Fusion Experts

Butt fusion is a versatile and reliable welding technique used for joining thermoplastic pipes and fittings in a wide range of industries. Its ability to create leak-free, long-lasting connections makes it an essential process for ensuring the efficient and safe transport of water, gas, chemicals, and more.

If your project requires any type of on-site plastic fusion work, the US FUSION team is here to serve you. Our technicians are ASME Section IX certified and have nearly four decades of HDPE and welded plastic pipe fusion experience. Get in touch to learn more about how we can help, or request a free quote online here.